This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MuchMoreWater purification technology

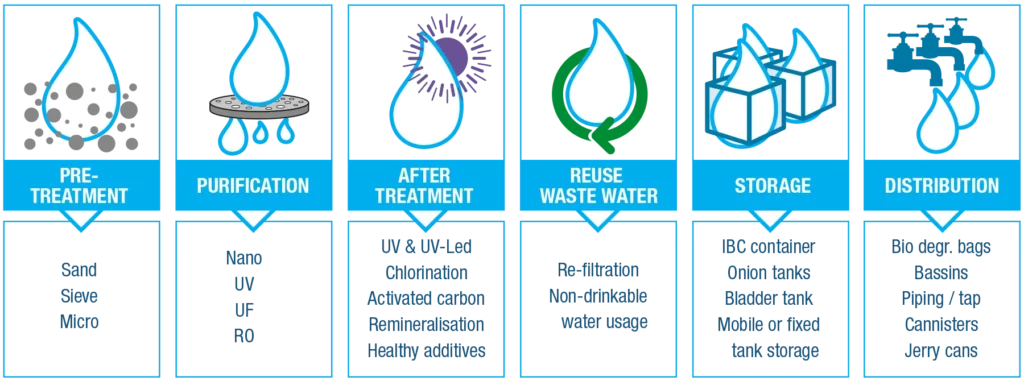

Selecting the right technology for emergency water purification is crucial for ensuring the health and well-being of individuals and communities in crisis situations. Our page is divided into three key sections:

- Prefiltration: Discover various prefiltration technologies that remove larger particles and impurities, setting the stage for effective water treatment.

- UV and RO Filtration. Explore how Ultraviolet (UV) and Reverse Osmosis (RO) filtration systems work to eliminate contaminants, highlighting their importance in emergency water purification.

- Post-Treatment: Learn about essential steps to optimize water quality after UV and RO filtration, ensuring safe and clean drinking water.

Choose the right tools and strategies to turn contaminated water into a source of hope and resilience during emergencies.

Filtration technologies and storage

Prefiltration

Prefiltration is a critical step in water treatment processes, particularly before employing advanced technologies like Ultrafiltration (UF) and Reverse Osmosis (RO).

This preliminary stage serves as the initial line of defense against contaminants present in the water source. By effectively removing larger particles, debris, and impurities, prefiltration not only extends the lifespan of UF and RO membranes but also enhances the efficiency and reliability of the entire water cleaning system. In the following sections, we will delve into various prefiltration technologies and their significance in achieving cleaner, safer water for a multitude of applications.

The optimal prefiltration can be decided based on a test of the intake water. If this is not available assumptions are considered.

Media Filters

Media filters use layers of granular materials like sand, anthracite, or multimedia to trap particles and impurities in water through physical filtration.

- Pros: Effective at removing sediment, silt, and larger particles. Simple operation and maintenance.

- Cons: May not effectively remove dissolved contaminants or very fine particles.

Filter houses

Filter houses are used with either cartridges or bags inside that can be replaced:

Filter cartridges consist of porous materials, such as pleated paper, fabric, or ceramic, which capture particles as water passes through.

- Pros: Easy to install, replace, and maintain. Can target specific contaminants using different cartridge types.

- Cons: Limited capacity and may require frequent replacement.

Filter bags are fabric-based filtration systems that capture larger particles and solids from water.

- Pros: Cost-effective, easy to change, and capable of handling high flow rates, can be cleaned, and reused.

- Cons: Limited to coarse filtration and may not effectively remove fine particles or dissolved substances.

Antiscalants

Antiscalants are chemical additives that prevent the formation of scale deposits, such as calcium and magnesium, on UF and RO membranes. Antiscalants are dosed into the water with a dosing pump.

- Pros: Protect membranes from scaling, improving their lifespan and efficiency.

- Cons: Need proper dosing and monitoring to be effective. Chemical handling and disposal considerations.

Activated Carbon Filters

Activated carbon filters use porous carbon, either granulate of solid, to adsorb organic compounds, chlorine, and certain chemicals from water. Important to have chlorine removed before using RO membranes as chlorine will destroy the membranes and some UF technology.

- Pros: Effective at removing taste, odour, and many organic contaminants. Enhances overall water quality.

- Cons: Limited to specific contaminants and may require periodic replacement or reactivation.

Sedimentation Tanks or Basins

Sedimentation tanks allow particles and solids in water to settle out under the influence of gravity before further treatment.

- Pros: Cost-effective for large volumes of water. Removes larger particles and allows for simpler subsequent treatment.

- Cons: May require significant space, and the efficiency depends on the settling characteristics of the particles.

Chlorine

Chlorin is sometimes used as part of prefiltration as this will both kill some organics like bacterial before reaching the RO and UF filters and will keep the prefiltration equipment clean from bacteria’s settling. You do however need to have the chlorine removed if you use RO membranes. This is done by either using activated carbon as described, or by adding chemicals like Bisulfide.

Some prefiltration technologies, like media filters and certain filter housings, offer an additional advantage – they can be backflushed.

Backflushing

Backflushing is a process where the flow of water is temporarily reversed to clean and unclog the filter media. This maintenance technique helps extend the lifespan of the filtration system and ensures consistent performance.

Pros of Backflushing:

- Extended Filter Lifespan: Backflushing removes accumulated debris, preventing clogs and prolonging the life of the filter media.

- Improved Efficiency: Regular backflushing maintains optimal filtration rates, ensuring effective contaminant removal.

- Cost Savings: Longer-lasting filter media reduces replacement and maintenance costs.

Cons of Backflushing:

- Water Usage: Backflushing requires additional water, which can be a concern in water-scarce regions.

- Energy Consumption: The reversal of flow may require energy to operate valves and pumps.

- Complexity: Backflushing systems can be more complex and may require regular monitoring and maintenance.

Each prefiltration method has its own advantages and limitations, and the choice depends on the specific water source, contaminants, and treatment objectives. Careful consideration of these factors is crucial in designing an effective water treatment system incorporating UF and RO technologies.

Main treatment – Reverse Osmosis and Ultrafiltration

This brief introduction serves as an initial exploration into the realms of Reverse Osmosis (RO) and Ultrafiltration (UF). The world of membranes and filtration is extensive, encompassing a rich tapestry of specialized technologies, each designed to yield unique outcomes. This introductory overview offers a general glimpse into the transformative potential of RO and UF processes, while acknowledging the intricacies of specialized membrane applications that yield diverse results.

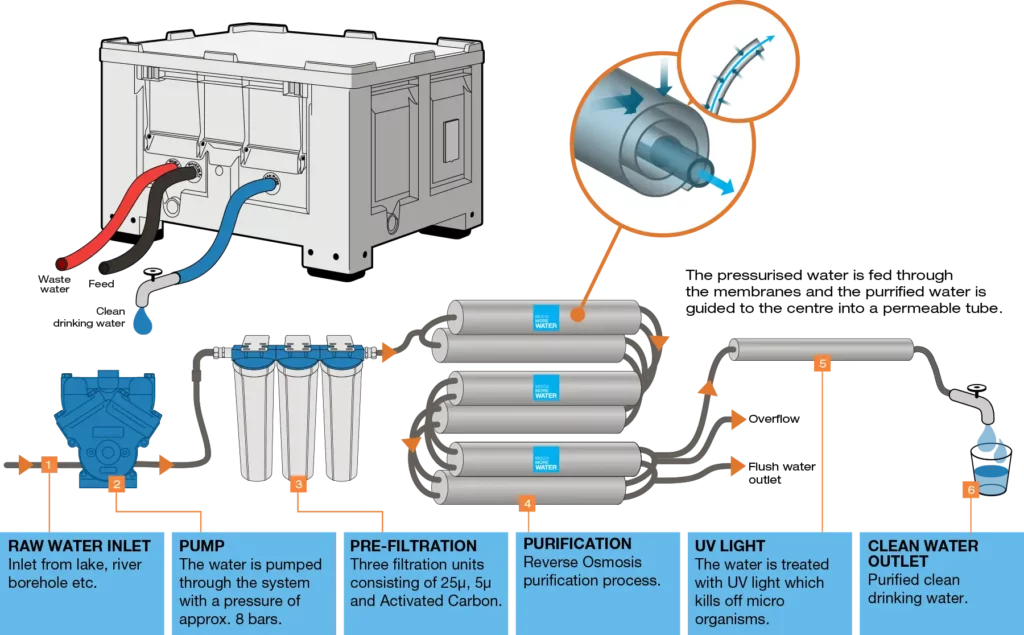

Diagramme of a Reverse Osmosis installation

Ultrafiltration (UF)

Ultrafiltration is a physical filtration process that uses semi-permeable membranes with relatively large pores, typically in the range of 0.01 to 0.1 micrometres. Water is forced through these membranes, which act like fine sieves, blocking particles, colloids, bacteria, and some large molecules from passing through. However, UF allows smaller molecules and ions to permeate, making it effective for separating suspended solids and microorganisms from water. UF typically clean 80-100% of the intake water into potable water and is not too sensitive to different water temperatures. UF production typically working with 3-4 bar pressure using less power than RO production.

UF applications

UF is effective at removing suspended solids, turbidity, bacteria, viruses, and larger molecules from water. It is used for producing high-quality drinking water from various sources, including surface water and groundwater, by removing particulate matter and microorganisms. UF is also applied in industrial processes, and wastewater treatment.

Reverse Osmosis (RO) – low salination

Reverse Osmosis is a membrane-based process that employs a semi-permeable membrane with extremely fine pores, typically in the range of 0.0001 to 0.001 micrometres. Water is pressurized and forced through the RO membrane. This process is designed to reject the passage of dissolved salts, ions, molecules, and particles, producing highly purified water by removing almost all contaminants. Reverse Osmosis is the only technology which can remove heavy metals such as lead, copper, barium, chrome, mercury, cadmium, nitrates, selenium, and other unwanted elements. In addition, dangerous poisons such as arsenic, fluoride and pesticides will be removed.

The pores in the Membranes are smaller than bacteria such as E. coli and the parasites Giardia and Cryptosporidium. This stops them from being transported along with the rest of your drinking water.

RO typically clean 50-70% of the intake water into potable water. RO membranes are sensitive to water temperature are normally measured for their productivity at 25 Celsius. Decreases in water temperature decrease the production level due to the size of molecules, and by 7-8 Celsius you generally do not have any production. RO production typically working with 8-12 bar pressure.

RO applications

RO is used for a wide range of applications, including desalination of seawater and brackish water to produce freshwater. It’s employed in industrial processes, such as the production of ultrapure water for electronics and pharmaceutical industries. RO is a key technology for producing high-quality drinking water from various sources, including groundwater and municipal supplies. Ro water is clean enough for hospitals to use it to clean wounds.

Desalination with Reverse Osmosis (RO)

RO desalination is a game-changer for regions grappling with water scarcity, providing a lifeline of freshwater from seemingly endless oceans. Its applications extend beyond drinking water, encompassing industrial processes, agriculture, and even spacecraft hydration systems. With the ability to produce highly purified water from the most saline of sources, RO desalination is a beacon of hope in the face of global water challenges. RO desalination typically clean 10-30% of the intake water into potable water. RO membranes are sensitive to water temperature are normally measured for their productivity at 25 Celcius. Decreases in water temperature decrease the production level due to the size of molecules, and by 7-8 Celcius you generally do not have any production. RO desalination production typically working with 50-60 bar pressure.

Advantages of RO desalination

- High Purity Output: RO desalination can yield potable water with purity levels exceeding 99%, making it suitable for various applications.

- Sustainable Water Supply: It offers a sustainable and reliable source of freshwater, vital for arid coastal regions.

- Versatility: RO desalination can adapt to different saline water sources, from seawater to brackish water.

Considerations:

- Energy Intensity: RO desalination demands substantial energy input, which can impact operational costs and environmental considerations.

- Concentrated Brine: The process generates concentrated brine as a byproduct, requiring proper disposal or treatment to minimize environmental impact.

In essence, RO desalination stands as a technological marvel, unlocking the potential of vast saline water reserves to meet the ever-growing global demand for freshwater. It represents an innovative solution to the intricate challenges posed by water scarcity, offering a pathway towards a more sustainable and hydrated world.

Key Differences in technologies

Pore Size: The main difference between UF and RO lies in the size of their pores. UF membranes have larger pores that allow the passage of certain ions and small molecules, while RO membranes have much smaller pores that reject virtually all solutes, including salts and ions.

Water Quality: RO produces extremely pure water, suitable for a wide range of applications, including drinking water. UF, while effective at removing microorganisms and suspended solids, does not remove dissolved salts and ions to the same extent as RO. Knowing your water source and the aim of your water production decides the technology.

In summary, UF and RO are both membrane-based water treatment technologies, but they differ in pore size, applications, and the level of water purification they achieve.

Post treatment and measurements

In the realm of water purification, achieving pristine quality goes beyond initial filtration techniques like RO and UF. Post-treatment methods are the final steps in refining water quality, making it safe, palatable, and in line with regulatory standards. This essential stage includes options such as UV disinfection, chlorination, pH adjustment, and remineralization, each with unique benefits to tailor water quality to meet specific needs, ensuring that the water you consume is not only pure but also tastes and feels just right.

UV Disinfection

UV (Ultraviolet) light disinfection is a chemical-free method that effectively destroys microorganisms like bacteria, viruses, and protozoa in water by damaging their DNA and RNA. Technically the water pass through a tube with UV light in the right frequency and dimension.

Advantages

- It does not alter the taste, odour, or colour of the water.

- It is a sustainable and eco-friendly process as it doesn’t involve the use of chemicals.

- UV treatment is highly effective against a wide range of waterborne pathogens.

Chlorination

Chlorination is a widely used method for water disinfection and pathogen removal. Technically chlorine is dosed into the water, typically to the level of 2ppm.

Advantages

- Chlorine effectively eliminates bacteria, viruses, and other pathogens.

- It offers residual protection to the clean water, helping to maintain water quality as it travels through the distribution system and into often dirty water bottles.

- Chlorine is a cost-effective and well-established method.

Remineralization

Remineralization is a process of restoring essential minerals, such as calcium and magnesium, to the purified water. This is typically used for RO water as the RO membranes removes all minerals from the water. Technically is it done by dosing minerals into the water or more ideally leaving water in a tank for 8-10 minutes with mineral granulates.

Advantages

- It enhances the taste and quality of the water, making it more palatable.

- Remineralization helps increase the pH value and maintain the pH balance of the water, reducing its corrosive properties.

- It provides important minerals that may be removed during the purification process, improving overall water health.

pH Adjustment

Adjusting the pH level of water can improve its taste and reduce corrosiveness. This is typically used for RO water as the RO process lower the pH level typically to 5-6 pH value. Technically you can dose chemicals like Bisulfide into the water or remineralize with a Calcium product.

Advantages

- pH adjustment helps prevent damage to plumbing systems caused by acidic water.

- It can enhance the overall aesthetic quality of the water for consumers.

These post-treatment options are essential to ensure that purified water is not only safe but also meets quality standards and is pleasant to drink. The choice of post-treatment methods may depend on the specific needs and characteristics of the water source and the preferences of consumers.

Further many chose to measure the quality of the potable water after the processes depending on preferences. This can be: pH level, TDS, conductivity, chloride among others.